Mechanical booster pumps

[Structure]

Two balanced cocoon-shaped rotors are fixed to two parallel shafts, and driven by motor.

While the rotors are rotated, gas sucked from the inlet port is enclosed in the space between the casing and the rotors, and continuously exhausted via the outlet port, which creates vacuum efficiently.

[Features]

- Extremely high exhaust performance

- Easy operation and maintenance

- Long operating-life

- Compact body and low vibrations

- Produces clean vacuum.

- Safe horizontal posture

[Selection of back pump]

Mechanical booster pump is not designed for compression or exhausting to atmospheric pressure. Its performance will vary depending on the type and performance of the back pump. Therefore, to configure an exhaust system using a mechanical booster pump, it is necessary that the most appropriate back pump be selected for user’s purpose of use.

- Select a back pump whose exhaust capacity is 1/2 to 1/10 of mechanical booster pump.

For continuous operation under relatively high operating pressure, select a large-capacity back pump. For continuous operation under relatively low operating pressure, select a small-capacity back pump. - In consideration of the performance characteristics of oil sealed rotary pumps and water-ring pumps, oil sealed rotary pump should be selected as a back pump for operation under high vacuum, and a water-ring pump should be selected for a process where a large volume of condensable gas is exhausted under low vacuum.

- Various pump combinations are available to fit specifications. Therefore, contact us for further information before selecting pumps.

SMB/SMB-C series

SMB-CM series

SMB-C06M use a magnetic coupling, which enables the pumps be driven from atmospheric pressure.

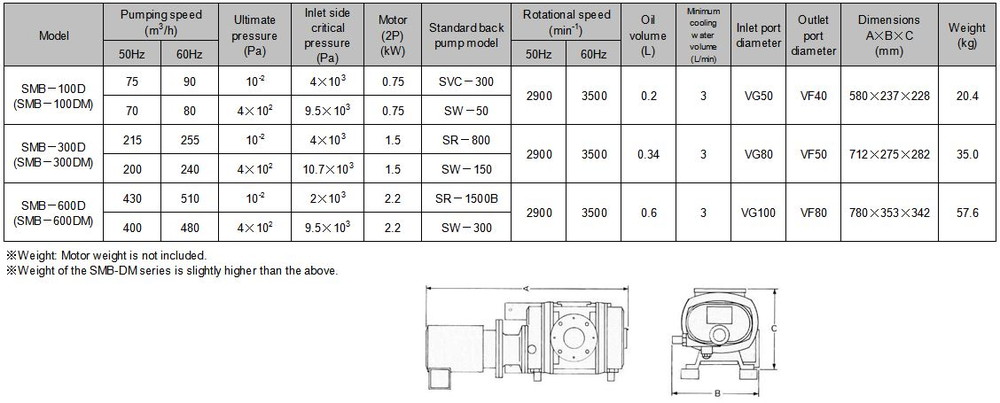

SMB-D (DM) series (Aluminum direct-connection type booster pump)

- The SMB-D (DM) series is made of aluminum as the principal material, resulting in light weight.

- Using the magnetic coupling makes it possible to drive the pump from atmospheric pressure, resulting in approx. 50% reduction in exhaust time. (DM series)