Atomosphere Plasma System type of SSC-AP series

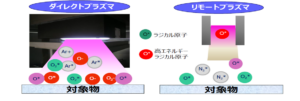

Atmospheric-pressure plasma systems are broadly divided into “Remote” and “Direct plasma” methods,

Although the majority adopt the remote method, in this approach the distance between the reactor and the substrate

causes the plasma activity to be significantly weakened, resulting in reduced treatment effectiveness.

[Features]

Shinko Seiki has partnered with APP Co., Ltd. and adopted their proprietary direct plasma head “ArP®”,

Discharge the target substrate with high-energy plasma, achieving performance close to CCP processing

even under atmospheric pressure,thereby enabling effective plasma surface treatment.

【Vacuum Plasma:CCP】

■Excellent uniformity performance

■High cleanliness

■By changing the etching gas, it can accommodate a wide range of objectives and applications.

■High initial installation cost and running cost

【Atomosphere Plasma】

■High throughput

■Low initial installation cost and running cost

■High design flexibility

■Low process gas consumption

■Conventional atmospheric-pressure plasma provides limited surface treatment effectiveness; ArP® enables to improvement

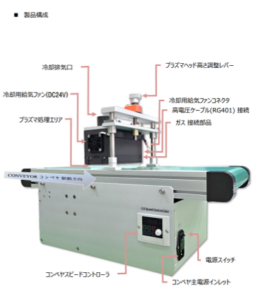

Type of ArP100C

Belt conveyor system (Belt width: 100 mm)

Variable belt speed

Discharge width: 100 mm

Discharge gap: max. 7 mm

Ar / O2 processing supported

RF power: typical max. 160-180 W

Gas flow rate: 1-4 L/min

Adjustable discharge gap (recommended: 3-4 mm or less)