Water ring vacuum pumps

[Structure and operating principle]

The body of water ring pumps is comprised of a cylindrical casing and impeller. The impeller is eccentric to the casing. While the impeller is rotated with an appropriate volume of water filled in the casing, the weight-heavy sealed water forms a concentric ring along the casing inner wall due to centrifugal force, as shown in the figure. As the volume between the impeller vanes and the casing inner surface changes, the pump continuously draw in, compress and exhaust gas via the intake and exhaust ports on the side wall or impeller inner wall. The high-speed rotation makes exhaust highly efficient. The water ring acts as a seal, so gas that has been sucked into the pump is assuredly exhausted.

[Features]

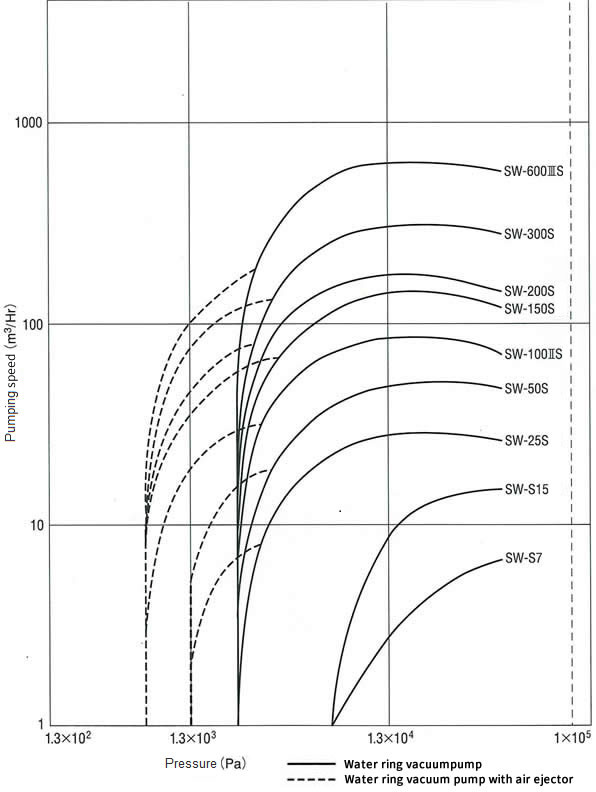

Owing to the water seal, the pumps can exhaust inflammable and corrosive gases. These water-ring type pumps are suitable for exhaust gas that contains steam and water droplets. The 2-stage pump configuration exhibits high performance under 3 × 104 Pa or lower pressures.

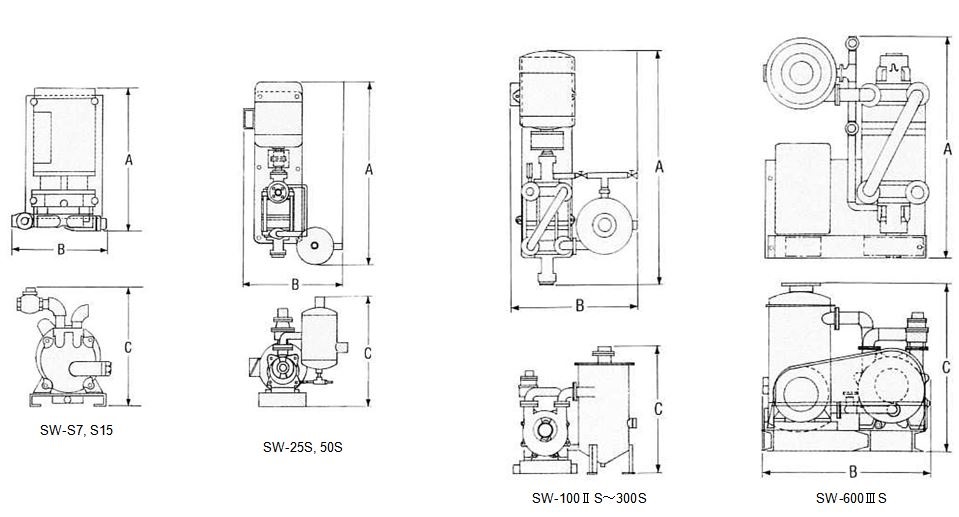

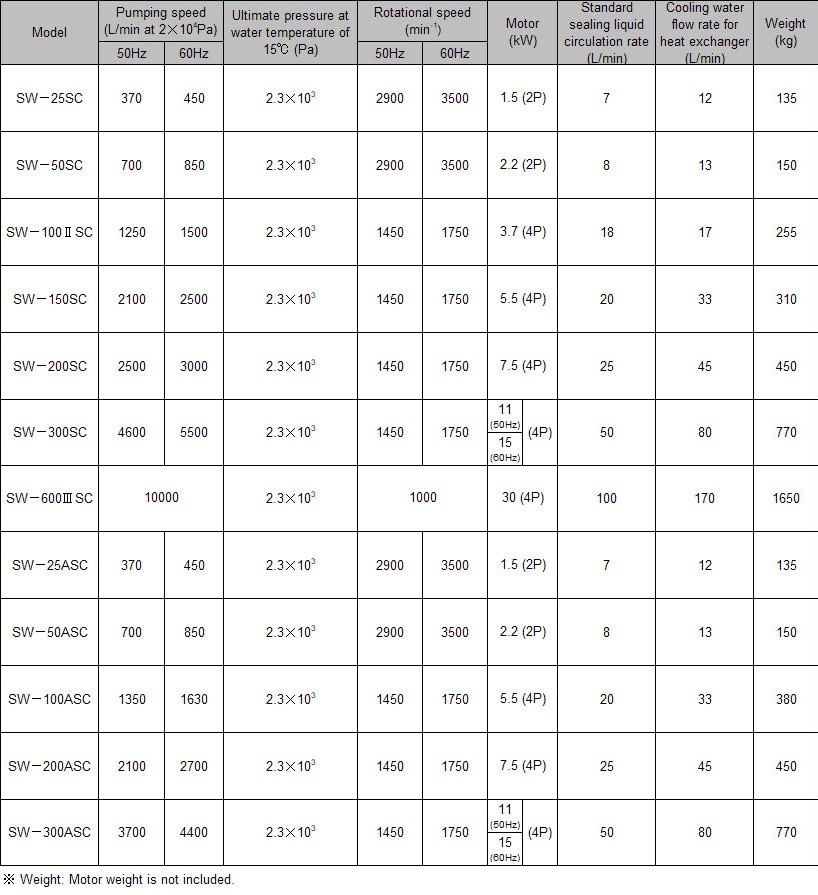

SW series Specifications

SW-AS series

SW-AS series pumps exhibit excellent corrosion resistance in corrosive gas suction processes. They are made of SUS316 or SCS14.

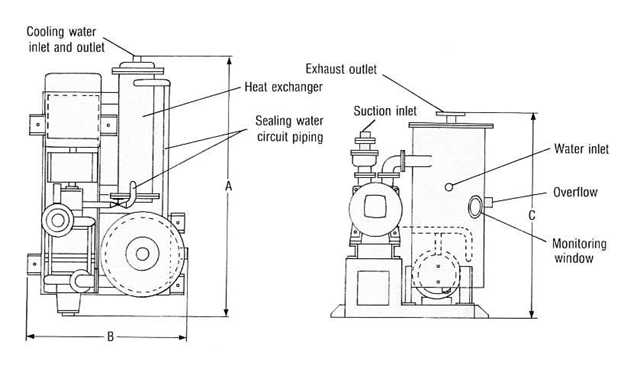

SW-C series

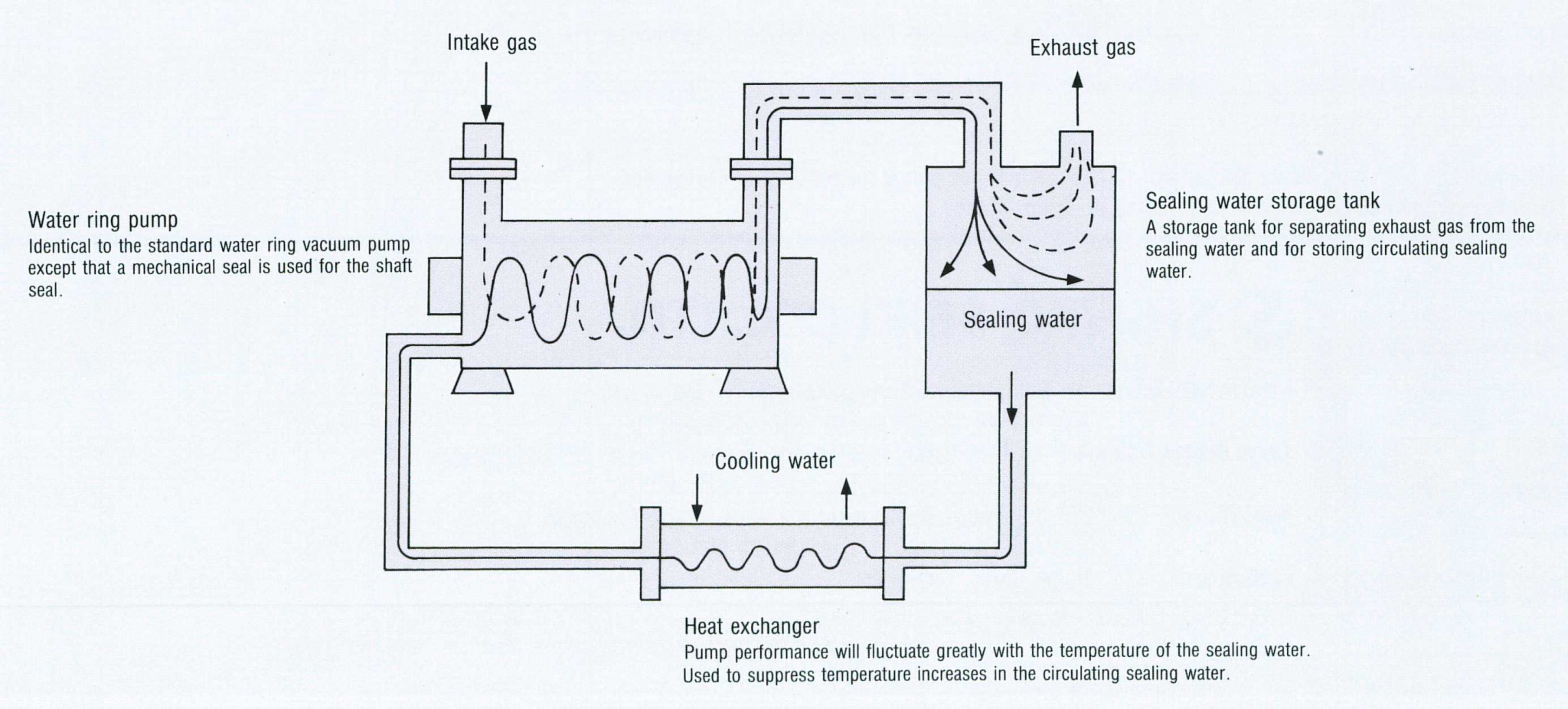

Gases that have been sucked into a pump can dissolve or mix in with the sealing liquid, and consequently be discharged from the pump as exhaust gas.

This may cause environmental pollution depending on the type of gas.

To prevent this problem, the SW-C series pumps circulate the sealing liquid inside, thus posing no threat to the environment.

The sealing liquid is cooled by the heat exchanger. The circulating circuit is a sealed structure.

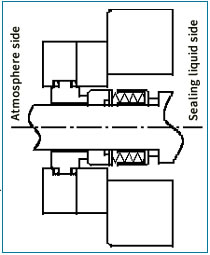

Mechanical seal type

Normally, the SW series uses gland packing for the shaft seal. However, a mechanical seal is also available on almost all models as standard specifications.

-

Pressurized by spring force, the seal system is automatically adjusted to wear of sliding surfaces and shaft vibration. With this structure, the free maintenance can be obtained. The packing does not need to be retightened or refilled to compensate for packing wear, and the shaft does not need replacing due to wear.

-

Seal materials slide on each other, causing no damage to the shaft. (With the gland packing type, the shaft is damaged by direct friction between the shaft and the packing, so the shaft must be replaced if seriously worn.)

-

The friction area and friction coefficient of the pump shaft seal are small. This structure reduces power loss, resulting in energy-savings.

- Highly reliable multi-springs are used. (For some models, a single spring is used.)

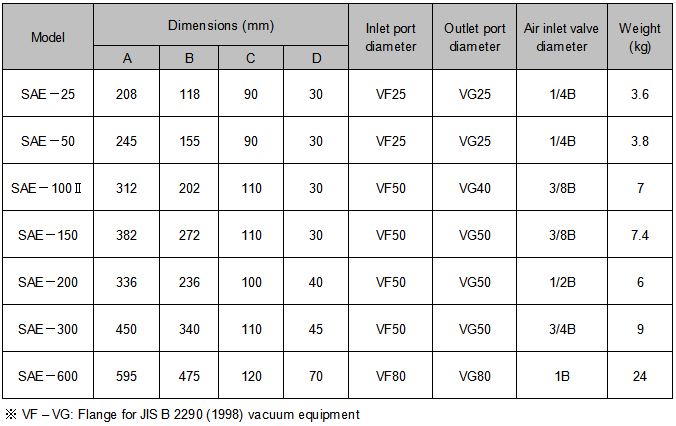

Optional accessories for water ring vacuum pumps

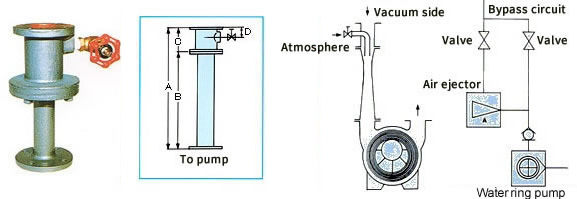

[Air ejector]

The air ejector is attached to the suction port of water ring pumps, to create a vacuum lower than the sealing liquid vapor pressure. The air ejector is driven by air introduction, so the pressure at the suction port of the pump is 8x 103 to 1.3x 104 Pa. Thus, pump operating noise can be reduced, and there is almost no change in driving power.